Many homeowners would be aware of how dirty their kitchen can get. Cooking in the kitchen does end up generating a lot of dirt and waste, especially liquid waste. If you were to leave the kitchen without cleaning it, you might end up having to deal with a host of issues. However, cleaning a domestic kitchen is simple enough. This is because domestic kitchens will usually have a specific number of users. Cleaning up a commercial kitchen though, is an entirely different ballgame.

Why Commercial Kitchens Require Grease Traps

Large institutions that use commercial sized kitchens will typically produce wastewater during activities such as the preparation of meals and dishwashing. These institutions could comprise schools, hotels, restaurants etc. The wastewater produced during these activities will generally contain oil, grease and suspended solid particles. In particular, facilities that use dishwashers, combi ovens and commercial woks often produce large amounts of liquid waste and grease.

In a vast majority of cases, the quantity or concentrations of these substances will be much higher than it is in the case of domestic kitchens. Left unchecked, these substances could end up accumulating in sewer pipes. For instance, high viscosity fats and cooking greases such as lard tend to solidify as they cool. Over time, they could lead to issues such as:

- Restricted wastewater flow

- Blocked sewers and drainpipes resulting in back-ups and,

- Foul odours

To prevent these issues from arising, health inspectors typically ensure that facilities with commercial kitchens install grease traps in their premises.

What is a Grease Trap?

Grease traps (or grease interceptors) have been around since Victorian times. But, it was only in the late 1800s that Nathaniel Whiting obtained the first patent for a modern day grease trap.

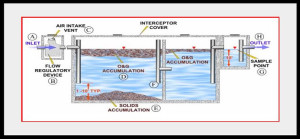

Grease traps are plumbing devices used for intercepting greases and solids before they enter a wastewater disposal system. They resemble boxes within the drain run that flow between the sinks in the kitchen to the sewer system. Usually made of stainless steel, cast iron, concrete or plastic, grease traps come in a wide range of capacities.

Because they accumulate large amounts of grease and fats, regular grease trap cleaning is a necessity. Therefore, the facility owners must ensure that they clean their grease traps on a weekly basis.

How Does a Grease Trap Work?

As mentioned earlier, grease traps are useful for reducing the amount of fats, oils and greases (or FOGs) that enter the main sewers. Wastewater from dishwashers and sinks typically enters the grease trap tank. This tank acts as a reservoir. It holds the wastewater and food that passes through the trap.

Solid food wastes will usually sink to the bottom because they are heavy. The wastewater in the trap cools the grease and oil to room temperature levels. As they cool, these substances harden (or solidify). The hardened substances float to the top of the grease trap. When they float to the top of the trap, they displace the liquid in the middle of the grease trap.

Grease traps usually have tube fittings that enable the rest of the wastewater to flow through towards the exit pipe. From here, it drains out into the sewer lines, leaving the FOG behind in the grease trap. Some grease traps could even have another tank for trapping additional grease that might have escaped from the first one. The process of filtration remains the same in the second tank as well.

Business and facility owners would need to carry out regular grease trap cleaning. Many service providers offer grease trap pumping services. Regular maintenance would ensure that the grease traps continue to function at optimal levels.

Guidelines from South Australia Water for Businesses with Commercial Kitchens

South Australia Water recommends that businesses with commercial kitchens must follow certain guidelines for mitigating issues associated with foul odours from drains, blocked drains, back-ups etc. Some tips include:

- Identifying and understanding the input sources to the wastewater stream

- Applying good work practices such as:

- Scraping spoiled food, waste food or scraps of food from plates and dishes into a bin prior to washing up

- Setting waste cooking oil aside for recycling rather than pouring it down the sink

- Turning off taps when not in use

- Using dishwashers only once there is a full load

- Avoiding the use of running water for thawing frozen food

- Installing sufficient pre-treatment devices for reducing the contaminant levels in wastewater from kitchens, sculleries etc.

- Facilities with grease traps would need to:

- Ensure that wastewater volumes and flow rates correspond to the design capacity of the grease trap

- Minimise wastewater temperature

- Minimise the amount of solids, oils and grease that enter the trap

- Use grease trap service providers for cleaning the trap regularly

- Using quick breaking detergents or biological additives for boosting the operation of the system

Hire the Leaders in Grease Trap Pumping to Keep Your Grease Trap Functioning at Optimal Levels

With over 20 years of experience in the business, Nitschke Liquid Waste is the name to bank on when you want to clean your grease trap. On receiving your call, our team of experts will visit your facility. They will also get the job done as quickly as possible. With us, you can expect the highest levels of service at the most affordable rates.

A well-maintained grease trap will give you years of use. It will also safeguard you from various health and hygiene related concerns when the health inspectors come calling. Call us at 8260 7660 for more details.

Image courtesy of JR Grease Services Inc.